"A Gloucester firm are said to have acquired a patent for the manufacture of a 12 lbs (5,4kg) bicycle which will carry a 14 stone (89 kg) man. One thousand machines are being made and they will soon be on the market."

"A Gloucester firm are said to have acquired a patent for the manufacture of a 12 lbs (5,4kg) bicycle which will carry a 14 stone (89 kg) man. One thousand machines are being made and they will soon be on the market."

"The Ingenious Mr. Pedersen" David E. Evans.

The first Mikael Pedersen's Cycles in production can be dated to between 1897 and 1899.

In the summer of 1899 Dursley-Pedersen Cycle Co. was founded.

Owners was Robert Asthon Lister (Later Sir Asthon) and his son Charles Lister, and Mikael Pedersen. They received license from the Pedersen Cycle Frame Co. Ltd. to make bicycles.

In 1917 the Dursley Pedersen Cycle Co. ceased to be.

Some firms continued making bicycles until 1921.

Mikael Pedersens account of how he came to create his unsual bicycle.

I have been a cyclist for more than twenty years, and have done much hard riding, some times 5000 miles in one season. I soon found there was much room for improvements in the construction of cycles, although it was only when I got my first safety that I saw how much yet remained to be done in this direction.

![]()

The Seat

The part of the machine in general use which I found especially imperfect was the seat. There have, it is true, been many attempts to make better seats, but none were what I thought completely successful, I made several experiments before I could get exactly what I wanted, but finally my efforts were crowned with success

|

|

The seat which I have devised is, as you will observe, made of strings of different degrees of tension, running from a point in front to cross steel bar giving the requisite width behind. In order to give the right width and form, cross strings are interwoven. The seat is suspended between two supporting points about two feet from each other; and running from the cross steel bar to the rear supporting point are several spiral springs, which afford the requisite elasticity. It will be seen that this seat (called by some the "hammock", and by others the "network" seat) can never become hard or too wide at any point, although it gives the rider more space than other seats.

|

|

|

As, moreover, it "gives" in every direction, the weight is always evenly distributed. You may take my word for it that all cyclist - and especially ladies - after once trying this seat will refuse to ride on any other. It's weight is not more than four ounces, as against the (about) 3 lb. of an ordinary saddle.

Seeing that I should want so much room between the two points for suspending the seat, I found it almost impossible to make a new seat frame which would not be too heavy, and which would have an elegant appearance.

It would be natural to describe the seat first, as Mikael Pedersen invented this first. And it was the "anatomy" of the seat that caused the construction of the frame. He invented a bicycle that fitted the seat. The original seat was woven as a net. The shape was wide at the rear end and narrow at the front. The material was either silk cord or wiped cord and some times thin leather cord, 45 yards (40 m) was used. The net made it very soft to sit on. The seat was supported at the front by an adjustable leather strap and could be tightened or slacked depending on the rider and by 7 springs at the rear, the seat yielded to the body weight and gave a more pleasant ride. The frame imparted a great lateral stability to the machine, and offered excellent resistance to pedal pressure.

And it was the "anatomy" of the seat that caused the construction of the frame. He invented a bicycle that fitted the seat. The original seat was woven as a net. The shape was wide at the rear end and narrow at the front. The material was either silk cord or wiped cord and some times thin leather cord, 45 yards (40 m) was used. The net made it very soft to sit on. The seat was supported at the front by an adjustable leather strap and could be tightened or slacked depending on the rider and by 7 springs at the rear, the seat yielded to the body weight and gave a more pleasant ride. The frame imparted a great lateral stability to the machine, and offered excellent resistance to pedal pressure.

Some seats were made with a leather cover like we know it today. Now a days, seats are made of imitated leather, but the principle is the same.

The Frame

I resolved to make a cycle frame which would carry the seat without the necessity of having a special seat frame at all. In ordinary "safety" I found the frames were so far from perfection that I had to abandon that system entirely, ![]() with the exception of the two tubes running from the bottom bracket to the rear wheel spindle.

with the exception of the two tubes running from the bottom bracket to the rear wheel spindle.

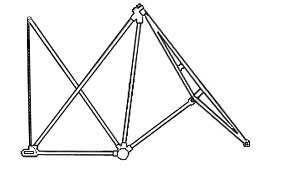

Now, in order to have a strong support in front for the suspension of the seat, and at the same time to hold the top pivot for the front fork, I let one tube from each end of the bottom-bracket tube run to supporting point, where they are joined. Two other tubes run from the supporting to the rear ends of the hind wheel fork, forming two perfect triangles, joined at the top angle; where they carry the seat from the  front fork pivot, and are held apart in the two other angles by the bottom-bracket barrel and spindle from the rear-wheel. This is the real body of the frame, and the great strength of it will easily understood.

front fork pivot, and are held apart in the two other angles by the bottom-bracket barrel and spindle from the rear-wheel. This is the real body of the frame, and the great strength of it will easily understood.

To form a strong support behind, from which the seat is suspended to its support in front, I build another tube from each end of the bottom-bracket barrel running to the required point, where they are joined; and from there a wire runs down on either side, where they are connected to the rear ends of the hind wheel fork, forming ![]() two other perfect triangles, joined at the top, and held apart beneath in same way as the above-mentioned triangles; the tubes running from the bottom bracket to the hind wheel spindle form the basis of the triangles in both cases.

two other perfect triangles, joined at the top, and held apart beneath in same way as the above-mentioned triangles; the tubes running from the bottom bracket to the hind wheel spindle form the basis of the triangles in both cases.

It will be seen that in no other way could equally strong supports for the suspension of the seat be made, unless at the sacrifice of lightness. Nothing like the common front fork could be fixed to this frame. I may say that I never approved of the manner in which these forks were built, in as much as they were weakest where they ought to be strongest, and heaviest where they ought to be lightest.

Description of the frame

The frame used a triangulated frame of small diameter tubing rods which were soft soldered together and plated inside and out. The triangle is a very strong and very stabile geometric figure. Mikael Pedersen got the idea from the Whipple-Murphy bridge construction where strength and lightness were desired.

This was what Mikael Pedersen wanted to obtain, lightness, strength and stability.

This was what Mikael Pedersen wanted to obtain, lightness, strength and stability.

The frame was made of 14 separate narrow diameter tubing rods, joined in 57 places, making 21 triangles throughout the bicycle. Regardless of the low weight of material of the bicycle it is strong enough to support a man of 14.28 stones (90 kg).

The construction of the frame is so strong that Mikael Pedersen was able to build a bicycle in wood only (Must be a kind of prototype). This special bicycle is displayed at the City Museum of Copenhagen.

The first frames were not adjustable, only the seat (back and forth). Due to customers complains, Mikael Pedersen later altered the construction so the seat could be adjusted vertically.

Later still the bicycle was produced in eight different sizes for men and three different sizes for ladies.

The very first frames that were produced, were lighter than 19.84 pounds (9 kg), lighter than contemporary bicycles. Later fabrications were a bit heavier, actually the frame got more and more heavy in time.

The Front Fork

I build my front fork of four tubes, which I join at the top, where they carry a pivot spindle.  About midway there is a crown plate, which carries the bearing for the pivot bolt, and keeps them apart, so that from there to the top the fork consists of four perfect triangles. On each side two tubes are joined at the lower end, thus forming a fork for the front wheel, each side consisting of a perfect triangle. Made in this way, the front fork is so strong that, although weighing only rather more than half a pound, it will carry a rider of sixteen stone over a rough road.

About midway there is a crown plate, which carries the bearing for the pivot bolt, and keeps them apart, so that from there to the top the fork consists of four perfect triangles. On each side two tubes are joined at the lower end, thus forming a fork for the front wheel, each side consisting of a perfect triangle. Made in this way, the front fork is so strong that, although weighing only rather more than half a pound, it will carry a rider of sixteen stone over a rough road.

To transmit the steering power to the front wheel the handle bar drops to allow room for the knees, thus enabling the bar to be built into the strongest part of the forks connecting all four tubes.

To transmit the steering power to the front wheel the handle bar drops to allow room for the knees, thus enabling the bar to be built into the strongest part of the forks connecting all four tubes.

The pivot spindle at the top of the fork is fitted into bearing at the top part of the frame from which the saddle is suspended. At this point the centre lines of all the eight tubes meet.

To hold the front fork at the right distance below, a tube is built out from each end of the bottom bracket, the tubes running towards the middle of the front fork, where they are joined, and carry a seat for a pivot bolt, by which it is pivoted to the crown plate in the front fork.

The bottom bracket barrel, which has to stand the heaviest strain of all parts of the frame, is, as I have shown, held by four tubes at each end; and this accounts for the immense strength of the frame.

By Mr David E. Evans: The Ingenious Mr. Pedersen, Appendix Two, Mikael Pedersens account of how he came to create his unusual cycle. It is taken from an early, undated catalogue, perhaps the first issued.

Frame sizes

Because of the limited adjustment possibilities, cycles were made in 8 sizes for men related to leg length and it was important to have the right size. Otherwise riding could be very uncomfortable.

Ladies frames came in three sizes, A, B and C but ladies legs were presumably unmentionable as leg length is not referred to.

The A size was equivalent to the 22 inch diamond frame cycle with 24 inch wheels and 6 1/2 inch cranks.

| Frame size | Inside leg length in inches (Inderseem) |

| 1 | 27 1/2 |

| 2 | 29 |

| 3 | 30 |

| 4 | 31 1/2 |

| 5 | 33 |

| 6 | 34 |

| 7 | 35 |

| 8 | 38 |

Frame Numbers

According to these frame numbers it is not likely that there have been produced as many as 30,000 bicycles.

| Main Frame No. | Approx. year |

| 1-400 | 1900 |

| 400-1600 | 1901-03 |

| 1600-2250 | 1904 |

| 2250-4000 | 1905-07 |

| 4000-6000 | 1907-11 |

| 6000-7800 | 1911-14 |

| Source: Mr. G. Hall - Gloucester, UK | |

Frame Colours

| Colours | Approx. year |

| Black, Green and Claret | 1905 |

| Grey, Black and Brown | 1910 |

| Kaki | 1911 |

| Grey | 1912 |

Head tubes

Mikael Pedersen invented two different "head tubes" to support his front-fork. One for ladies frames and one for gents frames.

Why he made them different I don't know. Later he made a "head tube" with a ball head, I assume he got the idea from the Cream separator.

Enlarge drawing

Manufacturing the frame

In 1896 Mikael Pedersen applied for a patent on his own way of molding the frame. The tubes were closed at the ends and placed in the bottom bracket. The frame got burnished and lowered into melted metal that tin soldered (soft solder) the frame and this secured rigidity and stability of the frame. The alloy of the melted metal is unknown today.

The frame was covered with a layer of copper, then a layer of nickel and then burnished again.

In the end the frame was enameled in different colors. All in all a very good work of quality.

In 1911 there were six Gents models, two of which were "Diamond framed" and 5 Ladies models, where two models also were "Diamond framed".

These bicycles could be supplied with a 3 speed gear.

There are some disagreement as to how many bicycles were produced, some say 30,000 pieces, others say 8,000 pieces. Mr. G. Hall - Gloucester has made a research in which the highest frame number he could find was no. 7800 (See Frame Numbers).

Head badges

Click head badges to enlarge

1893 - 1899 bicycles carried the Mikael Pedersen head badge.

1893 - 1899 bicycles carried the Mikael Pedersen head badge.

Text on the badge says:

THE PEDERSEN PATENT

MIKAEL PEDERSEN

MAKER

DURSLEY

1899 and up bicycles carried the badge commonly associated with Dursley-Pedersen bicycles.

1899 and up bicycles carried the badge commonly associated with Dursley-Pedersen bicycles.

Text on the badge says:

THE DURSLEY PEDERSEN

TRADE MARK

CYCLE DURSLEY ENG.

This head badge is form a 1907 model.

This head badge is form a 1907 model.

Text on the badge says:

THE DURSLEY PEDERSEN

TRADE MARK

MAKERS

R.A. LISTER & Co Ltd DURSLEY